January 12, 2021

January 12, 2021

The stability of a drug substance or product is a critical attribute for all pharmaceutical products. As such, stability testing is required throughout the drug development phase as well as post-approval and lifecycle management.

Essentially, stability testing is a means of measurement to assure that the drug substance or product is able to maintain its overall quality, purity, identity, and strength throughout its storage period under predefined storage conditions. In the International Conference on Harmonisation (ICH) guideline Q1A(R2), the FDA explains that “the purpose of stability testing is to provide evidence on how the quality of a drug substance or product varies with time under the influence of a variety of environmental factors, such as temperature, humidity, and light and to establish a retest period for the drug substance or a shelf life for the drug product and recommended storage conditions.” In addition to the environmental conditions, factors related to the drug substance/product’s characteristics such as formualtion, particle size, polymorphs, and crystalline structure to name a few, can also influence the stability profile.

Because stability testing requires a significant commitment of time, resources, product samples, and specific equipment, it’s a good idea for manufacturers to have a thorough understanding of the requirements and their responsibilities both during the development and post-approval phases. These are detailed in the Q1A(R2) guideline for both drug substances and products.

At the appropriate phases of drug development, the stability indicating tests should be developed, qualified, and validated, and should be able to sufficiently detect subtle changes in those attributes of the drug substance or product that are susceptible to change during storage and are likely to influence quality, safety, and purity. The testing should cover the physical, chemical, biological, and microbiological attributes.

According to Q1A(R2), at least 12 months of stability data from formal stability studies should be provided on at least three primary batches of the drug substance and drug product in the license application.

Typically, formal stability studies include long term (which would be the normal storage condition), accelerated (which would be considered the worst-case predictor of the long-term storage condition), and intermediate (utilized in event of a failure timepoint during the conduct of the long-term or accelerated stability study).

Two other stability studies include stress (intentional degradation or force degradation) and photostability (sensitivity to exposure to light) testing. In both types of studies, the results allow the Sponsor to determine and establish the impurity profile of the drug substance and drug product and would then be utilized for determination of those impurities that need to be monitored throughout lifecycle management for continued affirmation of safety of the product.

Stress testing of the drug substance or drug product can help identify the likely degradation pathways and the intrinsic stability of the molecule, and validate the stability indicating power of the analytical procedures used. As such, stress testing is a critical component in determining the stability profile of a product. The nature of the stress testing (oxidative stress, acid, base, light, and humidity) will depend on the individual drug substance and the type of drug product involved.

Photostability testing determines the substance’s or product’s sensitivity to light. If the substance or product is sensitive when exposed to light, the test will help determine what precautions need to be taken. For instance, the substance or product might need to be stored in a container (e.g. amber glass bottle or vial, aluminum pouch, etc.) that blocks out light to prevent degradation.

In-use stability testing is also required when a drug product is further manipulated (such as a powder that needs to be dissolved into a solution) prior to being administered to a patient to demonstrate and provide assurance to FDA that the end reconstituted product remains stable during that period of time.

Administering a comprehensive stability testing program in accordance with ICH Q1 requires relevant expertise, facility, and equipment. If a manufacturer does not have the capabilities to conduct such a program in-house and is not prepared to make the investment to set up the required infrastructure, equipment, and Quality Control laboratories, and maintain them throughout the assessment periods, then outsourcing the stability testing to a contract development and manufacturing organization (CDMO) is an option.

The right CDMO will have the operational and regulatory expertise necessary to conduct stability testing in an appropriate and ICH compliant manner.

Selecting a CDMO must be conducted with great care. It must be determined that the CDMO follows current good manufacturing practices (cGMPs) within its facility. The CDMO must also have the capacity to handle all required testing and controlled storage and stability chambers. Additionally, it’s best if the CDMO has market knowledge specific to the type of drug that is being developed, as this eliminates the learning curve and makes the testing process flow more smoothly.

While not mandatory, FDA guidances are just that, guidance/recommendations and, as such, FDA expects manufacturers to follow its recommendations as much as possible. In certain circumstances, for example, when the Sponsor has a unique drug substance or product that cannot undergo accelerated stability testing because the substance would degrade in a matter of seconds, they could seek a waiver because it is impossible for them to comply with the recommendations set forth in the guidance document. Being excused from the guidance in this manner will require providing the FDA with data that sufficiently supports the request and securing formal agreement from FDA.

Stability testing and subsequent establishment of a drug’s stability profile is an essential part of any drug development plan. However, the reality is that not all manufacturers have the in-house capability to operate or execute the required stability testing program. Whatever the nature of the drug being developed, and regardless of the drug’s stage of development, it helps to work with a regulatory consultant throughout the drug development process.

ProPharma Group is that partner, and we can assist with the selection of a CDMO, conduct mock-audits, and provide CMC stability advice as part of overall drug development including handling and reporting to FDA of related Out of Specification (OOS) results and compliance issues. Ultimately, having a partner in your corner provides peace of mind that your testing program is on track to support your drug development plan.

To learn more about our services and how we can help you through the entire drug development process, contact us today.

TAGS: Regulatory Sciences

July 16, 2024

The key to successful drug development in the US is directional and focused navigation of FDA’s Investigational New Drug (IND) process. The Chemistry, Manufacturing, and Controls (CMC) section is a...

March 11, 2021

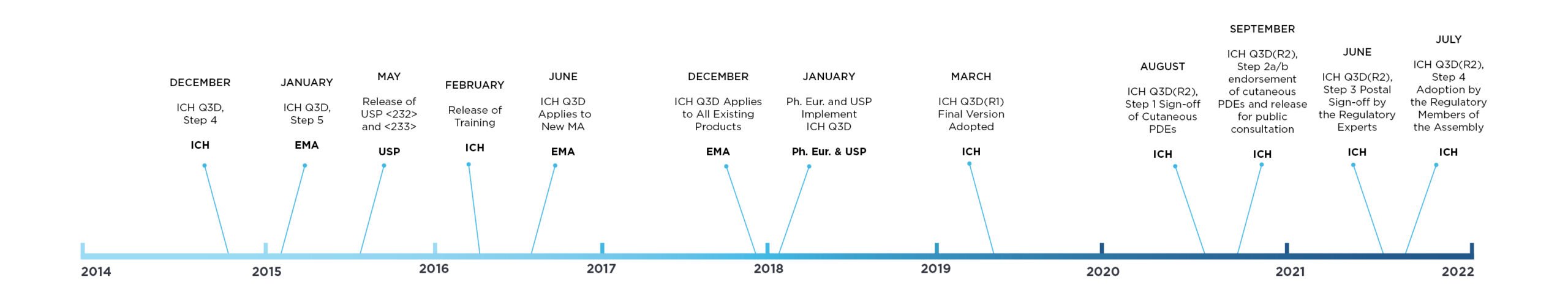

How to Manage the Risk of Elemental Impurities with ICH Q3D: The mission of the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) is to ensure...